Polyamide, commonly known as nylon (Polyamide, referred to as PA), its appearance makes textiles take on a new look and is a major breakthrough in the synthetic fiber industry. In the textile industry, nylon 6 and nylon 66 occupy almost “half of the country.”

However, traditional nylon is mostly derived from non-renewable petroleum resources, and the high temperature and high pressure production process causes high emissions of wastewater and carbon dioxide, which has a negative impact on the environment. In order to reduce the environmental burden and reduce environmental pollution, the environmental protection and sustainable value of green fiber products has gradually become prominent, and Bio-based nylon 56 came into being.

Ⅰ.PA56:Special fibre

PA66, developed in 1935, is named after the six carbon atoms contained in diamine and adipic acid. Due to the early time and significant advantages of PA66, the first to achieve industrialization, so in a long period of time after the publication of PA66 in the textile industry has been widely used.

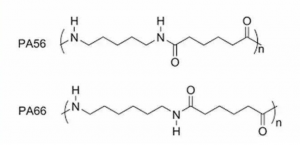

* Molecular structure comparison of PA56VSPA66

PA56 is a polyglutaryladipate diamine formed by the polymerization of bio-based glutaryldiamine and petroleum-based adipic acid. It is named for the fact that glutaryldiamine has one less carbon atom than hexamethylene diamine in PA66. PA56 inherits the basic characteristics of polyamide fibers, and at the same time, due to the different proportion of carbon atoms, gives the Bio-based nylon 56 unique microstructure, which has more unique advantages than PA66.

*PA66 material

Ⅱ.PA56:Green & Unique performance

Compared with PA66, PA56 is more environmentally friendly in the production path; In terms of application performance, due to the unique microstructure of PA56 “freeing hydrogen bonds”, the fabric is more flexible, more temperature resistant, and more dry.

1.More green

PA56 uses recycled plant raw materials, which can absorb atmospheric CO2 during plant growth and reduce the greenhouse gas impact factor in the whole life cycle. Compared to traditional petroleum-based PA66, bio-based PA56 can reduce the consumption of non-renewable resources by approximately 50%.

2.More flexible

Unlike PA66, PA56 contains unsaturated hydrogen bonds that retain biological “activity.” The unique Young modulus value of the material can scientifically adjust the touch of the fabric, provide strong and wear-resistant properties at the same time, give natural soft touch and excellent drape.

3.More temperature resistant

3.More temperature resistant

The fiber glass transition temperature (Tg value) of PA56 is 45-55 ℃, which is lower than that of PA66(60℃). Therefore, PA56 can remain soft in large temperature differences, and it is not brittle or hard to wear in some special regions, such as deserts, snowy mountains, and high altitude areas.

4.More dry

The thermal conductivity of PA56 is higher than that of PA66, the heat conduction is faster, and the contact cold sensation coefficient is higher. At the same time, the “active” structure in the molecular chain makes it have the ability to absorb water faster, and the heat is transmitted to the outside of the fabric, and the long-lasting wearing can also maintain the cool body feeling effect.

SYNTHOLUTION TECH is a global supplier of additives for the modification of plastics and coatings, including UV absorbers, antioxidants, light stabilizers and flame retardants, which have been widely used by customers in Europe, the United States and the Asia-Pacific region.

Enquiries are welcome at any time: little@syntholution.com

Post time: Jun-13-2023