Reactive light stabilizer

China's resin (broadly defined, any polymer compound that can be used as raw material for plastic products processing is called resin) industry is developing rapidly. Product output continues to expand, and the national industrial policy encourages the resin industry to develop in the direction of high-tech products. The variaties of China's resin have been relatively perfect, but compared with foreign advanced counterparts, there is still a certain gap in production scale, process control and some products with special performance requirements. Therefore, in the next few years, only the research and development of high-performance products, improve the stability of product quality, is the urgent matter of resin development, is also fundamental.

The resin material is easy to get aging, when it's exposed to light, the unsaturated double bond in the molecular structure or the impure material in the process is more likely to break the bond deterioration, free radical chain reaction, and induce the generation of color group, eventually leading to the resin fade and cracking. In order to solve the problem of photoaging of resin, it is necessary to add a photostabilizer to the resin in order to inhibit or delay the photoaging process and prolong its service life.

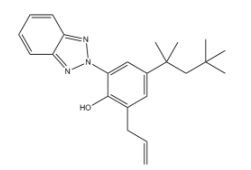

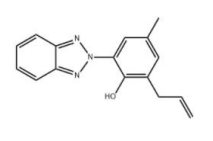

Light stabilizer is a kind of auxiliary agent which can inhibit or delay the photodegradation of resin. Throughout the development and research status at home and abroad, the development and research of light stabilizers shows some new trends and characteristics, to seek efficient, environmental protection, economic and meet the harsh processing and application environment of new varieties of light stabilizers, new structure has always been the goal of industrial development and research. In particular, it is an important development direction of light stabilizers to combine different functional groups in one molecule to make the molecule have multifunctional reactivity and improve its efficiency. By introducing the chemical bond of reactive monomer into resin branch chain or main chain, the reactive light stabilizer can play the characteristics of high strength and solvent resistance and light resistance of resin, which has a strong application prospect. The addition of reactive light stabilizer to the resin will not seriously affect the molecular structure of the resin, but can improve some properties of the resin itself defects, and then improve the processing performance and use performance of the resin, improve the use value and service life of the resin.

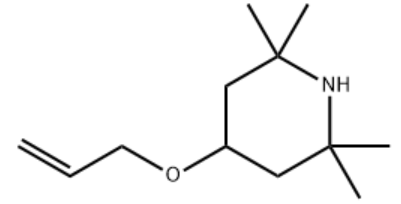

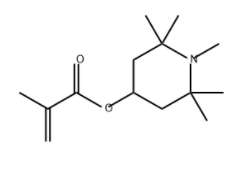

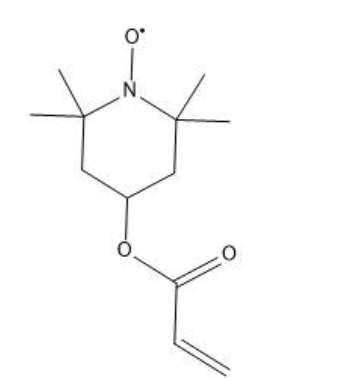

Reactive light stabilizer refers to the introduction of reactive groups into the molecular structure of the blocked amine, so that it is bonded or grafted onto the polymer backbone during the processing of the polymer products to form a permanent photostable polymer with blocked amine functional groups. This light stabilizer can well avoid the physical migration or volatilization caused by the loss of light stabilizer, improve and improve the dispersion of blocked amine light stabilizer in the polymer and the effect of light stabilization, especially after the polymer product material recycling and re-production, the light stabilizing group can still play a good light stabilization effect. The permanent bonding of the blocked amine molecule to the polymer backbone by reactive groups is an effective measure to solve the problem of permanent photostability of plastic products. Foreign companies including Japan Showa Denko, Adico, etc., have launched a methacrylate as a reactive group of light stabilization agent, with better light stabilization effect. But methacrylate group is not stable, in the synthesis of the need to add polymerization inhibitor to avoid the occurrence of self-polymerization, so it is inevitable to increase the difficulty of post-treatment. In addition, methacrylate is a volatile substance with moderate toxicity, which is harmful to operators.

The reaction light stabilizer have below advantages:

safe raw materials;

environmental friendly;

the catalyst is economical and efficient;

the preparation method is simple and the raw material price is low, which can be widely

used in industrial production, in order to develop applications in the fields of high-end electronic information chemicals and photoresist.