Bio-based materials—Nylon 56

Nylon (PA) is currently the most widely used materials in the field of clothing, mainly PA6 and PA66, because most of the production of nylon mainly relies on oil, facing the depletion of oil resources, in the production and application process will also produce environmental problems. The Bio-based nylon, using renewable biomass resources as raw materials, has the characteristics of green, environmentally friendly, renewable raw materials and so on. In terms of environmental protection and resource issues, PA56 has a strong substitute role for PA66 and PA6. At present, China’s independent research and development of bio-based PA56 has entered the industrialization stage.

After the country proposed the “double carbon” goal, the 14th Five-Year Plan and industrial development policies in many regions in China all involve the promotion policy of bio-based new materials. Data show that in practical applications, the use of one ton of bio-based PA56 fiber can save 160 liters of crude oil and reduce carbon dioxide emissions by about 7 tons. Biobased PA56 is of great significance for regional energy conservation and emission reduction.

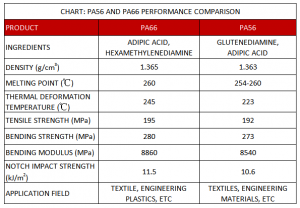

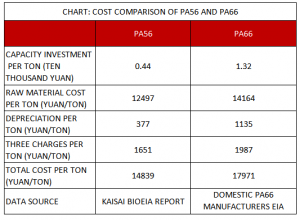

Look at the nature of the product, in the characteristics of the product itself, PA56 and PA66 density, melting point, strength and other characteristics are similar, PA56 hygroscopic better, higher oxygen index, low temperature dyeing better. In addition, according to Hua ‘an Securities data, from the cost side, the total cost of PA56 per ton is nearly 20% lower than PA66, which is also an important factor to promote PA56 to replace PA66.

Compared with domestic industrial development, domestic PA56 is better than PA66. Adipdinitrile is the key material for the preparation of PA66, the development of domestic PA66 has been limited due to the lack of adipdinitrile production equipment and technology, and the domestic demand for PA66 relies on imports from Europe, the United States and Japan. Until 2022, Tianchen Qixiang made technological breakthroughs to change the long-term monopoly situation abroad and accelerate the localization process of adiponitrile.

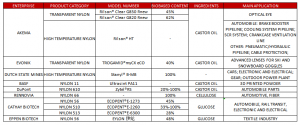

Different from countries with backward PA66 technology, the biosynthesis technology used in domestic PA56 is ahead of the international level. At present, nylon enterprises at home and abroad are layout of Bio-based nylon products, mainly castor oil route abroad, through a series of chemical transformation of the oil to prepare PA monomer and then synthetic Bio-based nylon, but the international market castor oil more than 90% dependent on India imports, from the raw material end of the lack of competitiveness, constraints are obvious.

In fact, there are not many domestic PA56 manufacturers, and it can even be said that it is relatively scarce. Among the listed companies, only Kesai Biology and Eppen Biology, a subsidiary of Star Lake Technology, can complete the preparation of Bio-kindragon 56 fiber. Both of them are based on corn, other starchy substances and straw as raw materials, and the technical route has obvious advantages over international manufacturers.

(Source: Akema official website, Evonik official website, DSM official website, BASF official website, DuPont official website, Kesai Biological Announcement, Star Lake Technology Announcement, Hua ‘an Securities Research Institute)

Overview of the industrial pattern of PA56, PA56 is more low-carbon environmental protection, and can solve the disadvantage of PA66 industrial technology subject to people. And the domestic initial formation of PA56 industrial advantages, domestic enterprises development competition pressure is small, in the 14th Five-Year period is expected to rapidly promote the application of enterprises. Overall PA56 is in the gold development cycle of the blue ocean market.

The downstream market demand is large, and the application in the textile field needs to be explored. Comprehensive PA56 performance advantages, its downstream use is very broad. It can be used for the skeleton fabric of rubber products such as tires, airbags, cables, etc., and can also meet the wearing needs of different categories of clothing. At the same time, there is also a great space for development in the engineering plastics industry, which can be applied to transportation, electronics, high-speed rail, mechanical bearings and other products.

According to the official statement of Kesai Biology, at present, its bioylglutenediamine has gradually begun to be applied in the fields of civil silk, industrial silk and engineering plastics. 50,000 tons of PA56 will be put into production in 2021, and it is expected that the new production capacity will reach 500,000 tons in 2023. Large-scale production capacity construction can also confirm the market demand and market prospects for PA56 from the side.

Different from Kesai Biology, Eppen Biology is aimed at the textile field, which is also the field of personal concern and more optimistic. Why pay special attention to textile and apparel? From the synthesis of chemical fibers to the processing steps such as clothing dyeing and leather tanning, there are environmental problems in many links, and clothing is the world’s second largest polluting industry. In the context of dual-carbon, it is no longer rare for luxury goods or high street brands to pay attention to sustainability, but a large number of clothing brands have begun to take measures to solve environmental problems, and low-carbon sustainability has become a trend.

In 2021, lululemon successively launched products using corn nylon and mushroom leather; In 2022, lingerie brand Jonei launched a “carbon-neutral underwear” using bio-based fabrics; The “World Citizen” regenerative environmental protection series launched by Anta’s FILA, the polyester fiber in the fabric is partly derived from bio-based; Li Ning launches new plant dyeing products……

Data show that in 2022, the total amount of fiber processing in China’s industrial textile industry reached 19.6 million tons, an increase of 1.1%. As the main raw material for industrial textiles, the output of nonwovens in China was 8.35 million tons, an increase of 1.8%. If bio-based materials are large-scale produced and promoted, then the market size will reach a trillion development scale, which is self-evident for corporate earnings. The iteration of new materials has begun to emerge, driven by the upsurge of new consumption and new fashion, bio-based materials meet the inner needs of modern people to return to nature, or it is a new starting point for industrial change.

SYNTHOLUTION TECH is a global supplier of additives for the modification of plastics and coatings, including UV absorbers, antioxidants, light stabilizers and flame retardants, which have been widely used by customers in Europe, the United States and the Asia-Pacific region.

Enquiries are welcome at any time: little@syntholution.com

Post time: Jul-17-2023