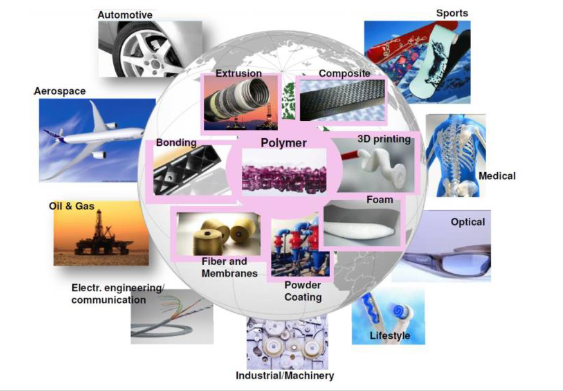

Polyamide (PA), also known as nylon, is a polymer containing amide groups in repeating units on the molecular backbone. Nylon can be made into a variety of plastics, drawn into fibers, and can also be made into films, coatings and adhesives. Because nylon has good mechanical resistance, heat resistance, wear resistance and other properties, products can be widely used in clothing, industrial yarn, automobiles, machinery, electronic and electrical, transportation, packaging industry and many other fields.

Nylon downstream applications are extremely wide

Source: the official website of Lianchuang, Changjiang Securities Research Institute

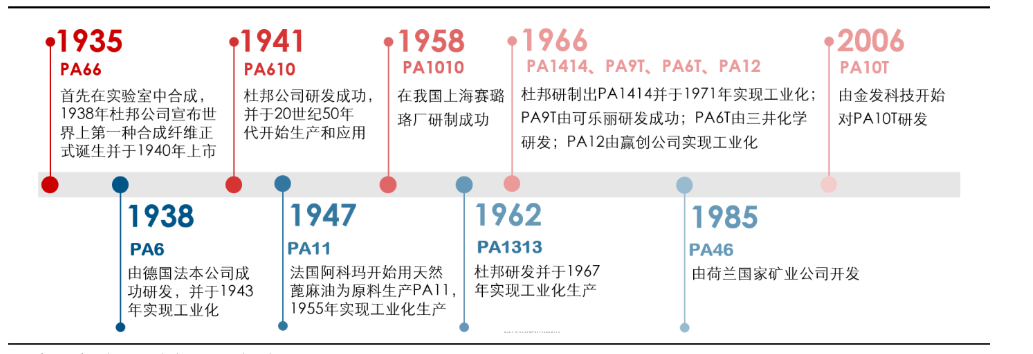

The nylon family continues to grow, and the performance of special nylon is better

Nylon has a long history and a growing family. In 1935, PA66 was synthesized for the first time in the laboratory, and in 1938, DuPont officially announced the birth of the world’s first synthetic fiber and named it nylon. In the following decades, the nylon family gradually developed, and new varieties such as PA6, PA610, and PA11 continued to appear. PA6 and PA66. With mature production processes and a wide range of applications, PA6 and PA66 are still the two most demanded types of nylon products.

The development history of nylon products

Source: China Textile Industry Research Institute, Changjiang Securities Research Institute

Nylon can be divided into aliphatic, semi-aromatic, full aromatic, etc. according to the chemical structure of the main chain. Aliphatic polyamide is a linear polymer material, which is regularly alternately linked by methyl chain segments and amide groups, and has good toughness. The introduction of aromatic rings into the backbone can limit the movement of the molecular chain and increase the glass transition temperature, thereby improving the heat resistance and mechanical properties of nylon products. When one of the raw materials of polyamide contains a benzene ring, a semi-aromatic polyamide can be prepared, and when both raw materials contain a benzene ring, a full aromatic polyamide can be prepared. Semi-aromatic polyamide heat resistance, mechanical properties are enhanced, and has good dimensional stability and solvent resistance, full aromatic polyamide has ultra-high strength, high modulus, high temperature resistance, acid and alkali resistance, radiation resistance and other excellent properties, but because its highly symmetrical main chain structure contains dense benzene rings and amide groups, so the processing performance is slightly inferior, difficult to achieve injection molding, its cost is relatively higher.

Molecular structure of different types of polyamide

Source: China Textile Industry Research Institute, “Structural Properties and Applications of Semi-aromatic Nylon”, Changjiang Securities Research Institute

Classification and characteristics of polyamide

| classification | varieties | synthetic method | Structural characteristics | characteristic |

| Aliphatic group(PAp)

|

PA6PA11

PA12

|

By ring-opening polymerization of amino acids or lactams, p represents the number of carbon atoms on the monomer carbon chain | Linear polymer material, composed of methyl chain segments and amide groups regularly alternately linked | Good toughness |

| Aliphatic group(PAmp)

|

PA46PA66

PA610 PA612 PA1010 PA1212

|

It is formed by polycondensation of aliphatic diamine and aliphatic diacid, m represents the number of carbon atoms contained in the diamine that constitutes the backbone part, and p represents the number of carbon atoms contained in the diacid that constitutes the backbone part | ||

| Semi aromatic(PAxy)

|

MXD6PA4T

PA6T PA9T PA10T

|

It is formed by polycondensation of aromatic diacids and aliphatic aditic adiamines, or aromatic diacids and aliphatic diacids, x represents the abbreviation of the number of carbon atoms or diamine contained in the main chain part of the diamines, and y represents the number of carbon atoms or diacids contained in the main chain part of the diacid | The side groups on the induced molecular chain destroy the regularity of the molecular chain and inhibit crystallization | Heat resistance, mechanical properties are enhanced, water absorption is reduced, and it has good dimensional stability and solvent resistance |

| Aromatic group | PPTA(Aramid 1414)PBA(Aramid 14)

MPIA(Aramid 1313) |

Polycondensation of aromatic diacids and aromatic diamine can also be formed by self-condensation of amino acids | The molecular chain skeleton consists of alternating benzene rings and amide groups | Ultra-high strength, high modulus, high temperature resistance, acid and alkali resistance, radiation resistance |

Source: China Textile Industry Research Institute, . Structural properties and applications of semi-aromatic nylon, Changjiang Securities Research Institute

Compared with conventional varieties, special nylon with new synthetic monomers has better performance. Even after modification, conventional nylon (PA6, PA66, etc.) still has shortcomings such as strong hydrophilicity, high temperature resistance, and poor transparency, which limits its application range to a certain extent. Therefore, in order to improve the shortcomings of conventional nylon and add new characteristics, a series of special nylon with different properties can be obtained by introducing new synthetic monomers to adapt to more use scenarios. These specialty nylons include high-temperature nylon, long carbon chain nylon, transparent nylon, bio-based nylon, and nylon elastomer.

Types and characteristics of special nylon

| Special nylon | varieties | characteristic | application |

| High temperature nylon | PA4T、PA6T、PA9T、PA10T | Attractive rigid aromatic monomer, can be used in an environment above 150 °C for a long time | Automotive parts, mechanical parts, electrical and electronic parts, etc |

| Long carbon chain nylon | PA11、PA12、PA612、PA1212、PA1012、PA1313 | The number of sub-methyl groups in the molecular chain is more than 10, which has the advantages of low water absorption, good low temperature resistance, dimensional stability, good toughness, wear resistance and shock absorption | Automobiles, communications, machinery, electronic appliances, aerospace, sporting goods and other fields |

| Transparent nylon | PA TMDT、PA CM12 | Light transmittance can reach 90%, better than polycarbonate, close to polymethyl methacrylate; In addition, it has good thermal stability, impact toughness, electrical insulation, etc | Automobiles, electronic appliances, industrial consumer goods, optics, petrochemicals and other fields |

| Bio-based nylon | PA11 (Raw material is castor oil) | The synthetic monomer comes from the extraction route of biological raw materials, which has the advantages of low carbon and environmental protection | Auto parts, electronic appliances and 3D printing industry |

| Nylon elastomer | PEBA | The molecular chain is composed of polyamide chain segment and polyether/polyester segment, which has the advantages of high tensile strength, good elastic recovery, high low temperature impact strength, low temperature resistance and excellent antistatic performance | Hiking shoes, ski boots, silenced gears, medical conduits, etc |

Source: Aibon Polymer, Changjiang Securities Research Institute

The advantages of PA12 in long carbon chain nylon are highlighted

Long carbon chain nylon has excellent performance, and nylon 12 has both performance and cost advantages. Nylon with a methylene length of more than 10 between the two amide groups in the nylon molecular backbone is called long carbon chain nylon, and the main varieties include nylon 11, nylon 12, nylon 612, nylon 1212, nylon 1012, nylon 1313, etc. Nylon 12 is the most widely used long carbon chain nylon, in addition to most of the general properties of general nylon, it has low water absorption, and has high dimensional stability, high temperature resistance, corrosion resistance, good toughness, easy processing and other advantages. Compared with PA11, another long carbon chain nylon material, the price of PA12 raw material butadiene is only one-third of PA11 raw material castor oil, which can replace PA11 in most scenarios, and has a wide range of applications in automotive fuel pipes, air brake hoses, submarine cables, 3D printing and many other fields.

Performance comparison of nylon

| performance | PA6 | PA66 | PA612 | PA11 | PA12 | PA1212 |

| Density (g/cm3) | 1.14 | 1.14 | 1.07 | 1.04 | 1.02 | 1.02 |

| melting point(℃) | 220 | 260 | 212 | 185 | 177 | 184 |

| Water absorption [24h(%) in water] | 1.8 | 1.2 | 0.25 | 0.3 | 0.3 | 0.2 |

| Water absorption [equilibrium (%)] | 10.7 | 8.5 | 3 | 1.8 | 1.6 | 1.4 |

| Tensile strength(MPa) | 74 | 80 | 62 | 58 | 51 | 55 |

| Elongation at break (23 °C, %) | 180 | 60 | 100 | 330 | 200 | 270 |

| Elongation at break (-40°C, %) | 15 | 15 | 10 | 40 | 100 | 239 |

| Flexural modulus (MPa) | 2900 | 2880 | 2070 | 994 | 1330 | 1330 |

| Rockwell hardness (R) | 120 | 121 | 114 | 108 | 105 | 105 |

| Heat deflection temperature (0.46MPa,℃) | 190 | 235 | 180 | 150 | 150 | 150 |

| Heat deflection temperature(1.86MPa,°C) | 70 | 90 | 90 | 55 | 55 | 52 |

Source: Development and Application of Nylon 12, Liyue Chemical, Changjiang Securities Research Institute

Later, we will outline the overall landscape of the nylon industry, and focus our research on the supply and demand of the nylon 12 industry.

The application is multi-point flowering, and the demand for nylon is strong

The growth nylon market is growing steadily, and specialty nylon performs better

Global demand for nylon continues to grow, with China as an important market. According to Reports and Data, the global nylon market size reached $27.29 billion in 2018, and the market size is expected to continue to grow at a compound rate of 4.3% in the future, and this figure is expected to increase to $38.30 billion in 2026. The Asia-Pacific region is an important market for nylon consumption, while the Chinese market is even more critical. According to the data of Lingao Consulting, the compound growth rate of China’s nylon market scale from 2011 to 2018 reached 10.0%, and in 2018, due to the rise in the volume and price of nylon products, the overall domestic market size reached 101.23 billion yuan, a year-on-year increase of 30.5%. From the perspective of consumption data, benefiting from the rapid development of the domestic economy, the apparent consumption of nylon products in China has reached 4.327 million tons in 2018, and the compound growth rate from 2011 to 2018 has reached 11.0%.

The scale of China’s nylon market continues to grow

The apparent consumption of nylon industry in China continues to grow

Source: Lingao Consulting, Changjiang Securities Research Institute

Source: Ling Ao Consulting, General Administration of Customs, Changjiang Securities Research Institute

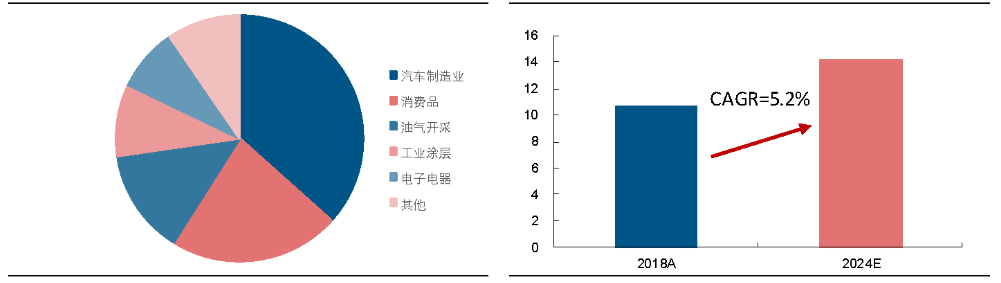

The market size of special nylon accounts for nearly 10%, of which nylon 12 accounts for the highest proportion. According to MRFR data, the global specialty nylon market size was $2.64 billion in 2018, accounting for about 9.7% of the total. The demand for lightweight and green energy saving of automobiles is the biggest driving force for the growth of special nylon market demand, and it is expected that the global special nylon market will continue to grow at a rate of 5.5% in the future, which is higher than the overall nylon industry. In the entire special nylon market, the largest product in the market is nylon 12, which can be used in plastic alloys, automobile manufacturing, aircraft manufacturing, 3D printing, electronic appliances, mechanical appliances, medical technology, oil and gas industry and other fields, with strong irreplaceability. According to MRFR data, the global nylon 12 market size reached $1.07 billion in 2018 and is expected to grow gradually to $1.42 billion in 2024 at a compound growth rate of 5.2%.

Distribution of Downstream Applications of Nylon 12 (2018)

Nylon 12 global market size steadily growing (US$ billion)

Source: MRFR Analysis, Changjiang Securities Research Institute

Source: MRFR Analysis, Changjiang Securities Research Institute

Below we analyze the application of nylon 12 in automobiles, 3D printing, oil and gas extraction and many other fields.

Demand growth is driven by the trend of lightweight vehicles

In the downstream demand structure of nylon 12, the largest application market is the automobile manufacturing industry, and the application of nylon 12 in the automotive manufacturing industry accounted for 36.7% of the overall market revenue in 2018. Automotive lightweight is a major trend in today’s automotive industry, to reduce the weight of the car, without compromising safety and comfort, the most mainstream solution is to replace the metal parts in the car. Nylon 12 can be widely used in automotive fluid transportation pipelines, including fuel lines, clutch lines, vacuum brake supercharger lines, air brake lines, battery coolant lines and the joints of the above pipelines, because of its safety and reliability, it is an excellent automotive lightweight material.

Part of the application of nylon 12 in automobiles

Source: UBE website, Changjiang Securities Research Institute

Compared to metal and rubber materials, nylon 12 offers significant advantages. Compared with metal materials, nylon 12 material is lightweight, which can reduce the weight of the whole vehicle and thus reduce energy consumption; Good flexibility, easy to arrange, can reduce the joint, not easy to deform by external impact; Good vibration and corrosion resistance; The joint has good sealing and easy installation; Extrusion is easy and the process is simple. Compared with rubber materials, pipelines made of nylon 12 material have thin walls, small volume and light weight, which do not affect the space arrangement; Good elasticity, can maintain elasticity under extreme temperature conditions and excellent aging resistance; No need for vulcanization, no need to add a braid, simple processing technology.

The spread of lightweight vehicles and new energy vehicles is driving demand for nylon 12. About 70% of automotive hoses (brake pipes, oil pipelines, clutch hoses, etc.) in Europe use nylon 12 material, and 50% of automotive hoses in the United States use nylon 12 material. In order to promote the construction of an automobile power, SAE China is entrusted by the National Strategic Advisory Committee for Manufacturing Power and the Ministry of Industry and Information Technology, and more than 500 experts in the industry have researched, compiled and released the “Technology Roadmap for Energy-saving and New Energy Vehicles”, listing “automotive lightweight technology” as one of the seven major technical routes, and putting forward the goal of reducing the weight of the vehicle by 10%, 20% and 35% in 2020, 2025 and 2030 compared with 2015, and the trend of lightweight is expected to drive the growth of demand for lightweight materials. In addition, with the development of new energy vehicles, nylon 12 is required for fuel systems and battery systems for both electric and hybrid models. As the impact of the epidemic gradually subsides, the production and sales of automobiles and new energy vehicles in China are expected to return to growth, which will continue to drive the demand for nylon 12 to further expand.

China’s automobile production and sales

Production and sales of new energy vehicles in China

Source: China Association of Automobile Manufacturers, Changjiang Securities Research Institute

Source: China Association of Automobile Manufacturers, Changjiang Securities Research Institute

Irreplaceable 3D printing materials

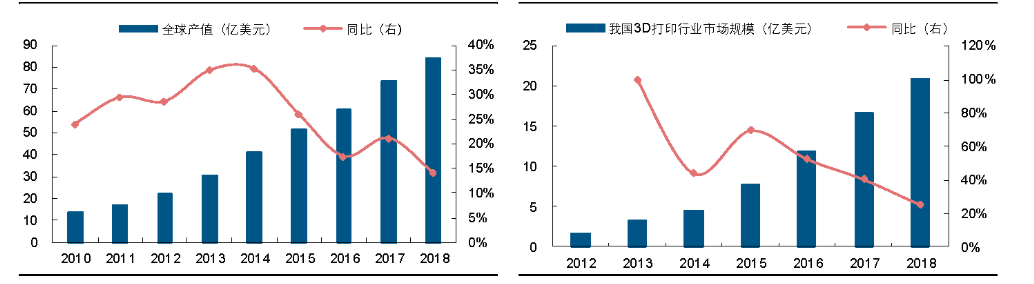

The global market for 3D printing is growing rapidly, and the pace of industrialization in China has accelerated significantly. Additive manufacturing (3D printing) has a profound impact on traditional product design, process flow, production line, factory mode, and industrial chain combination due to its ability to quickly manufacture various forms of structural organization, and has become one of the most representative and concerned disruptive technologies in the manufacturing industry, and is known as the core technology of the “third industrial revolution”. According to Wohlers Associates, the global 3D printing industry output value increased from $1.33 billion in 2010 to $8.37 billion in 2018, with a CAGR of 25.9%. China’s 3D printing technology started late compared with European and American countries, but the pace of industrialization has accelerated significantly in recent years. According to the statistics of the Prospective Industry Research Institute, the market size of China’s 3D printing industry only reached 160 million US dollars in 2012, and it has grown rapidly to 2.09 billion US dollars in 2018.

The output value and growth rate of the global 3D printing industry

The scale and growth rate of China’s 3D printing market

Source: Wohlers Associates, Wind, Changjiang Securities Research Institute

Source: Former Industry Research Institute, Changjiang Securities Research Institute

Materials are an important material basis for the development of 3D printing technology. The performance of materials determines whether 3D printing can have a wider application, and it is also the bottleneck that currently restricts the development of 3D printing. According to statistics from Markets and Markets, the global market size of 3D printing materials has exceeded $1 billion in 2018 and is expected to exceed $4.5 billion in 2024. According to the data of the Prospective Industry Research Institute, the scale of China’s 3D printing materials market has maintained rapid growth, from 260 million yuan in 2012 to 2.99 billion yuan in 2017, and it is expected that the market size of China’s 3D printing materials is expected to exceed 16 billion yuan in 2024.

Global 3D printing materials market size 2017-2024 (US$ billion)

2012-2024 China’s 3D printing materials market size (100 million yuan)

Source: Market and Markets, Changjiang Securities Research Institute

Source: Prospective Industry Research Institute, Changjiang Securities Research Institute

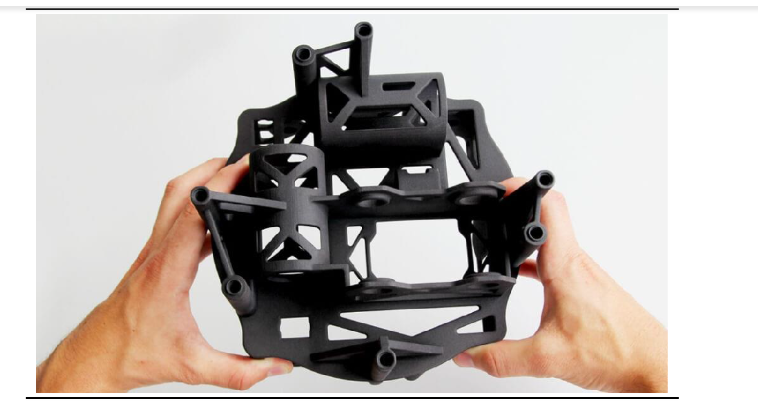

Nylon 12 material performs well in 3D printing. Compared with other materials, PA12 powder has excellent characteristics such as high fluidity, low static electricity, low water absorption, moderate melting point and high dimensional accuracy of products, fatigue resistance and toughness can also meet the needs of workpieces requiring high mechanical properties, so nylon 12 has gradually become an ideal material for 3D printing of engineering plastics.

Application of PA12 in 3D printing

Source: Sculpteo website, Changjiang Securities Research Institute

Comparison of 3D printing material properties (out of 5)

| 3D printing materials | strength | appearance | detail | Flexibility |

| Nylon PA12 (SLS) | 5 | 4 | 4 | 4 |

| Nylon. PA11/12 (SLS) | 5 | 4 | 4 | 4 |

| Nylon 3200 Glass Fiber Reinforced (SLS) | 5 | 1 | 1 | 2 |

| Aluminides (SLS) | 4 | 4 | 3 | 1 |

| PEBA (SLS) | 4 | 3 | 3 | 5 |

| Nylon PA12 (MJF) | 5 | 4 | 4 | 4 |

| Opaque photosensitive resin (PolyJet) | 4 | 5 | 5 | 2 |

| Transparent photosensitive resin (PolyJet) | 4 | 5 | 5 | 2 |

| Aluminum AISi7Mgo,6 (SLM) | 4 | 2 | 3 | 0 |

| Stainless steel 316L (DML S) | 4 | 2 | 3 | 1 |

| Titanium 4Al-4V (DMLS) | 4 | 2 | 3 | 0 |

| Sterling silver (cast) | 4 | 5 | 4 | 2 |

| Brass (casting) | 4 | 5 | 4 | 2 |

| Bronze (casting) | 4 | 5 | 4 | 2 |

Source: Sculpteo website, Changjiang Securities Research Institute

According to the statistics of the Prospective Industry Research Institute, PA12 was the fourth largest material in the global 3D printing industry in 2017, accounting for 5.6%, and in 2018, China’s nylon 3D printing materials accounted for 14.1%. The development of domestic nylon 12 materials in the future will lay the foundation for the development of China’s 3D printing industry.

Global 3D printing materials market structure in 2017

The market structure of 3D printing materials in China in 2018

Source: Qianqi Industry Research Institute, Changjiang Securities Research Institute

Source: Prospective Industry Research Institute, Changjiang Securities Research Institute

High-performance materials for the oil and gas transmission industry

Oil and gas transport places extremely high demands on materials. PA12 material has been used in onshore and offshore flexible risers, gas pipes, linings, steel pipe coatings for many years, which can prevent seawater erosion and corrosion of oil fluids, and is used to manufacture flexible risers for transporting subsea oil and gas products and merged fluids, natural gas distribution systems at pressures up to 20bar, etc., which have excellent service life and better corrosion protection than other materials, and are high-performance materials for the vigorous development of the oil and gas transportation industry. As a gas transmission pipeline, PA12 has been used for more than ten years. Compared with the metal pipes used in traditional sub-high pressure or high pressure gas transmission, PA12 gas pipelines can extend the service life of the pipeline and significantly reduce the cost of pipeline laying and subsequent maintenance. China proposed in the “Thirteenth Five-Year Plan” that during the “Thirteenth Five-Year Plan” period, about 5,000 kilometers of crude oil pipelines, 12,000 kilometers of refined oil pipelines and 40,000 kilometers of new natural gas trunk and supporting pipelines will be built, providing new impetus for the development of PA12.

PA12 gas pipeline installation site in Beckum, Germany

Source: Changjiang Securities Research Institute, official website of the company

Environmentally friendly and reliable cable and wire sheath

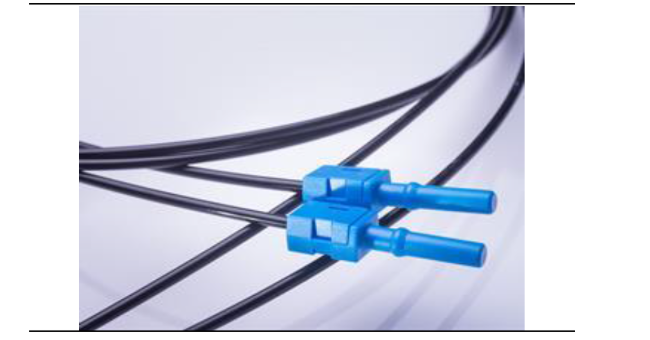

. PA12 can be used for submarine cables and floating cable cladding materials, cable anti-ant sheath, optical fiber sheath. Nylon 12 has low embrittlement temperature and excellent weather resistance, which is especially suitable for the manufacture of field special purpose communication cables required for all-climate (-50~70 °C). Used as submarine cable and floating cable cladding materials, it must consider the special environment and special working conditions in marine use, so the wire is required to have a small outer diameter, wear resistance, withstand a certain water pressure, sufficient tensile strength, and sufficient insulation resistance in seawater. Nylon 12 is a good electrical insulator, will not affect the insulation performance due to moisture, even if it is placed in water (or in seawater) for a long time, its insulation resistance is still very high, at least an order of magnitude higher than other nylon materials, the application of PA12 material cladding wire corrosion effect is good, impregnated on the seabed for three years without change. Cable anti-mosquito sheath was previously made by PE, PVC with insecticide or brass tape wrapping method, there are high cost, inconvenient maintenance, environmental pollution, ecological damage, unstable validity period and other deficiencies, the application of nylon 12 sheath is currently a more reliable and environmentally friendly method. In addition, the signal loss of optical fiber sheath made of PA12 material is the lowest among synthetic materials, so it is widely used in optical fiber communication cable sheath.

Nylon 12 for plastic optical fiber (POF)

Source: Changjiang Securities Research Institute, official website of the company

Photovoltaic, electrical, coating, packaging, medical fields have their own talents

In recent years, electrical parts are required to run with low noise, and components made of nylon 12 can be silenced, and are widely used in tape recorders, clock gears, electrical wiring and small precision mechanical parts. The resistivity of nylon 12 changes greatly with temperature, and the holding change is small, which can be used to manufacture temperature sensing components of electric blankets and electrical carpets.

Coated with nylon 12, the coating film has the best wear resistance, so it is often used in the production of high-grade coatings and adhesives. PA12 can be used in the bowl rack of the new dishwasher to ensure that the metal bowl rack is not worn out in the environment of high-temperature cleaning agents and has a longer service life; It can also be applied to outdoor furniture, such as park benches, which can effectively prevent metal corrosion after coating PA12.

PA12 film transparent, non-toxic, water vapor and gas (Oz, N2, CO2) transmittance is low, stored in boiling water for one year performance unchanged, and polyethylene blown extrusion composite film can be used to produce film sheet, with it to protect and package food, with the advantages of fragrance, steam sterilization resistance and low temperature good. Nylon 12 has good adhesion to metal, and when bonding food, the sealing value is 100%, and the peeling strength is high.

PA12 is also used as a nursing medical material, where the mechanical properties of the catheter material are particularly important, and the catheter made must be easy to thread, but not bent and never break. PA12 is an excellent material for catheter production due to high burst pressure, good flexibility, chemical resistance, compatibility with body fluids and non-toxic, in line with the requirements of the US Food and Drug Administration and the European Union for medical products.

Foreign companies monopolize the supply, domestic production is expected to break through the rapid development of the nylon industry, and there is still a gap in high-end categories

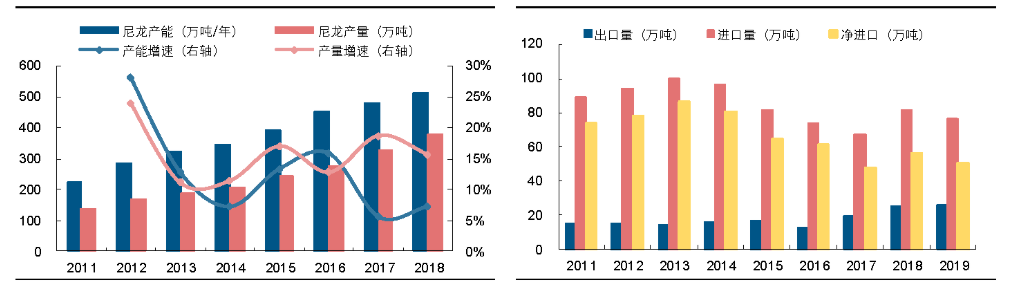

China’s nylon production capacity is growing rapidly, but high-end products still need to be imported. In recent years, benefiting from the increase in the domestic supply of caprolactam, the main raw material of nylon 6, and the rapid pull of downstream demand, China’s nylon production technology has been rapidly improved, and production capacity has entered a stage of rapid development. In 2018, the annual production capacity of China’s nylon industry reached 5.141 million tons, CAGR=12.7% from 2011 to 2018, and the output also grew rapidly with production capacity, with an output of 3.766 million tons in 2018 and a CAGR=15.8% from 2011 to 2018. From the perspective of import and export data, China’s nylon industry has maintained net imports, with a net import volume of 508,000 tons in 2019, especially some high-end products still have high import dependence, and there is a large space for import substitution in the future.

China’s nylon production capacity continues to grow

In recent years, the import and export of nylon industry in China

Source: Lingao Consulting, Changjiang Securities Research Institute

Source: General Administration of Customs, Changjiang Securities Research Institute

Technical barriers create high concentration, and oligopolies monopolize the nylon 12 market

The mainstream production process of nylon 12 is oxime method, and the technical barriers are high. Nylon 12 is usually prepared by cyclododecatriene (CDT) and laurolactam ring-opening polycondensation using butadiene as raw material, and the process includes oxime method, optical nitrosation method and Snya method, of which oxime method is the mainstream process. The production of nylon 12 by oxidation oxime method needs to go through 7 steps, such as triperization, catalytic hydrogenation, oxidation, ketification, oximization, Beckmann rearrangement, ring-opening polymerization, etc., and the whole process uses benzene, fuming sulfuric acid and other toxic and corrosive raw materials, the ring-opening polymerization temperature needs to be 270-300 °C, and the production steps are difficult to operate. At present, most manufacturers represented by Evonik use the mainstream process route of butadiene as raw material, and after Japan’s Ube Industries obtained the technology license of British Petrochemical Company, it adopted the process route of cyclohexanone as raw material to achieve the industrial production of PA12.

Synthetic route of nylon 12

| Synthesis process | Detailed introduction |

| Oxidation time-based method | Using butadiene as raw material, CDT was synthesized under the action of Ziegler catalyst, hydrogenated to generate cyclododecane, then oxidized to generate cyclododecane, dehydrogenated to generate cyclododecane, cyclododecone oxime hydrochloride was generated, and laurolactam was obtained by Beckmann rearrangement rearrangement rearrangement, and finally polycondensation to obtain nylon 12 |

| Optical nitrosation method | Under the irradiation of high-pressure mercury lamp, cyclododecane is reacted with nitrosyl chloride to obtain cyclododecone hydrochloride, laurolam is obtained by translocation of concentrated sulfuric acid, and finally polymerized to obtain nylon 12 |

| Snyafa | This method was invented by the Italian company Snia Viscosa, using cyclododecylcarboxylic acid or its salt as raw material, in the presence of sulfuric acid or fuming sulfuric acid, so that it and the same amount or excess of nitrosating agent to prepare high-purity laurythromide and polymerize to generate nylon 12 |

| Cyclohexanone method | A certain proportion of cyclohexanone, hydrogen peroxide and ammonia are catalyzed by carboxylate or ammonium salt to obtain 1,1-peroxide dicyclohexylamine, which is decomposed into 1,1-cyanoundecanoic acid by heating, and by-products caprolactam and cyclohexanone. Caprolactam can be used to prepare nylon 6, while cyclohexanone can be recycled. Next, 1,1-cyanoundecanoic acid is reduced with hydrogen, and finally W aminododecanoic acid is obtained, which polymerizes to generate nylon 12 |

Source: Development and Application of Long Carbon Chain Nylon 11, 12 and 1212, Changjiang Securities Research Institute

Under the oligopoly, the nylon 12 industry concentration is extremely high. In the 70s of the 20th century, nylon 12 was first industrialized by Degussa of Germany, the predecessor of Evonik Industries (Evonik), and then Swiss EMS, French Arkema and Japan’s Ube Industries (UBE) also announced the news of industrial production, and the four major manufacturers have firmly mastered the production technology of nylon 12 for nearly half a century. At present, the global production capacity of nylon 12 exceeds 100,000 tons/year, of which Evonik has a production capacity of about 40,000 tons/year, ranking first. In 2014, INVISTA filed a number of patent applications for nylon 12 raw materials, hoping to enter the nylon 12 resin market, but so far there is no news of production.

Due to the concentrated competitive landscape, supply-side emergencies will have a greater impact on the supply of the entire market. For example, on March 31, 2012, Evonik’s factory in Marl, Germany, caused an explosion due to a fire leakage, affecting the production of key raw material CDT for more than 8 months, resulting in a serious shortage of CDT supply, which in turn led to a tight global supply of PA12, and even caused some downstream automobile manufacturers to be unable to start normally. It was not until the Evonik CDT plant was put back into production at the end of 2012 that the supply of nylon 12 gradually resumed.

To meet strong demand, the giant announced plans to expand production. In order to meet the strong downstream demand for PA12 materials, in 2018, Arkema announced that it will increase its global PA12 material production capacity by 25% at its Changshu campus in China, and is expected to start production in mid-2020. Germany’s Evonik has also announced a €400 million investment to expand its PA12 material production capacity by 50 percent at the Marl Industrial Park, which is scheduled to start operations in early 2021.

Some PA12 production facilities in Marl

The nylon 12 industry concentration is extremely high

Source: Evonik website, Changjiang Securities Research Institute

Source: Changjiang Securities Research Institute

With the help of policies and policies, domestic enterprises are facing difficulties

Domestic enterprises have tackled long carbon chain nylon, and some varieties have made breakthroughs. In the 50s of the last century, China began to try to localize the production of special nylon represented by long carbon chain nylon, but due to complex process routes, harsh production conditions, many synthesis steps, high cost and other factors, until the 90s, China’s long carbon chain nylon industrial production was still stagnant. During the “Ninth Five-Year Plan”, the nylon research team of Zhengzhou University and the Institute of Microbiology of the Chinese Academy of Sciences jointly undertook the national key scientific and technological research plan, researched and developed the industrial production technology of preparing PA1212 by bio-fermentation of dodeca-carbodiacid, and cooperated with Shandong Zibo Guangtong Chemical Company to achieve industrial production, in addition, Shandong Guangyin New Materials Co., Ltd. also made breakthroughs in PA610, PA612, PA1012 and other varieties.

PA12 is more difficult, and breakthroughs can be expected with the help of policies. In 1977, Jiangsu Huaiyin Research Institute of Chemical Industry and Shanghai Institute of Synthetic Materials cooperated to carry out the synthesis of nylon 12 with butadiene as raw material. Subsequently, Baling Petrochemical Co., Ltd. (formerly Yueyang Petrochemical General Plant) carried out a small-scale synthesis study of nylon 12 with cyclohexanone as raw material, but due to the synthesis route of PA12 up to 7 steps and extremely high barriers, domestic enterprises have not yet achieved industrial production, and PA12 still relies on imports. In recent years, China has also continuously introduced policies to encourage the development of special nylon industry, actively promote the localization process of special nylon materials, with the help of policies, domestic enterprises will continue to face difficulties, is expected to break the monopoly pattern of PA12.

The policy encourages the development of special nylon industries such as long carbon chain nylon

| Published time | Publishing agency | name | content |

| 2016/10/14 | Ministry of Industry and Information Technology | Petrochemical and Chemical Industry Development Plan (2016-2020) | Accelerate the development of long carbon chain nylon and high temperature resistant nylon |

| 2016/11/25 | China International Engineering Consulting Co., Ltd. cooperates with 11 industry federations and associations, including China Machinery Industry Federation, China Iron and Steel Industry Association, and China Petroleum and Chemical Industry Federation | Investment Guide for Technological Transformation and Upgrading of Industrial Enterprises (2016 Edition) | The focus and direction of investment in the “Thirteenth Five-Year Plan” period were proposed, including high-temperature resistant nylon, long carbon chain nylon, etc |

| 2019/8/30 | China International Engineering Consulting Co., Ltd. cooperates with 11 industry federations and associations, including China Machinery Industry Federation, China Iron and Steel Industry Association, and China Petroleum and Chemical Industry Federation | Investment Guide for Technological Transformation and Upgrading of Industrial Enterprises (2019 Edition) | The central task of China’s industrial development in the next 10 years includes high-performance fiber industries such as high-temperature resistant nylon and long carbon chain nylon |

Source: Ministry of Industry and Information Technology, China International Engineering Consulting Co., Ltd., China Machinery Industry Federation, etc., Changjiang Securities Research Institute

Post time: Nov-14-2022